When choosing the perfect insulation for your home, you want something that will keep your space comfortable while also being energy-efficient. Cellulose insulation has been gaining popularity due to its eco-friendly nature and effective ability to regulate temperature. It helps decrease your energy bill by preventing heat loss in winter and reducing temperature drops in summer. Unlike some existing materials, it has an excellent R-value, which means it does a great job of keeping your home’s warmth intact. Additionally, installing cellulose is a solution for difficult-to-reach places, making it a choice worth considering.

However, like any product, there are drawbacks to delve into before making an informed decision. While numerous advantages exist, such as its ability to fit into tight spaces and its rise in prominence in the market, it doesn’t always last as long as other options. The material may lose some efficiency over time, especially if exposed to moisture. If you suppose longevity is your priority, you might need to evaluate whether it’s the best fit for your budget and age of the building. That said, for those seeking an effective and proper insulation set, cellulose remains a critical contender in the industry.

Understanding Cellulose Insulation

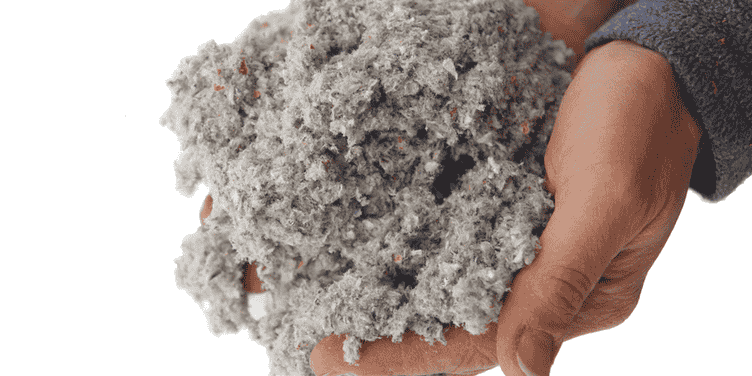

Cellulose insulation is a blown-in material made from recycled organic sources like paper, cardboard, and wood. This hybridized blend is densely packed to prevent unwanted airflow, helping to keep your home warm in the winter and cool during the summer. In addition, it is treated with non-hazardous chemicals such as borax, which helps repel insects and adds resistance to fire.

Cellulose Insulation Materials

Cellulose insulation is made from recycled materials, mainly paper fibers like newsprint, which are chemically treated to help them stick together and prevent issues like compression and settling. This process also helps deter pests and increase heat resistance, making it a reliable choice for homeowners. In most cases, the fiber has a pulpy texture, which some might visualize as shreds, but it is actually packed closely to provide additional protection. Since the installing process can be dusty, it is considered a messy but effective proposition. When laid at the appropriate thickness, these small particles fit together well enough to offer strong heat resistance. Being relatively sustainable, this insulation material is a common choice for those seeking an eco-friendly option.

Types of Cellulose Insulation

There are different types of insulation products, but when it comes to cellulose, the main form is blown-in loose-fill. This method requires professionals to use specialized blower equipment to spray fibers into areas like attic joists, floor spaces, and nooks and crannies that other materials might not reach. If you’ve ever wondered what is blown-in insulation made of, it typically consists of recycled materials like paper, cardboard, and wood fibers.

Also Read: What Is Vermiculite Insulation?

Unlike spray foam, which expands, cellulose is applied through a different process that involves blowing rather than rolling or scattering by hand. This allows installers to apply the material at an adequate thickness for full coverage, ensuring a complete seal. While cellulose is always made from recycled materials, homeowners can also consider fiberglass or mineral wool as alternative options.

Understanding the R-Value of Cellulose Insulation

The R-value is a unit of measurement that describes how effectively an insulation product resists heat flow. Manufacturers use a formula to calculate this value based on temperature (°F), hours of exposure, and square feet, with BTU (British Thermal Units) being the standard unit. A higher R-value generally indicates better resistance to heat transfer, but it’s important to note that it is not directly proportional to thickness—adding thicker layers doesn’t necessarily mean achieving higher R-values.

Installing Cellulose Insulation

Installing cellulose insulation is a detailed process that requires professionals and specialized equipment to ensure proper coverage and safety. Since this type of insulation creates significant dust and contains chemically treated fire-resistant materials, installers must follow strict safety measures. The process involves several key steps:

- Donning protective gear like masks, gloves, and other necessary equipment before starting.

- Removing any old insulation, storage boxes, pest debris, and dirt from the attic or designated space to prepare for the installation.

- Creating a clear path from the attic hatch or installation access point to the main door for easy movement of workers and materials.

- Transporting and setting up the specialized blower to distribute the cellulose in an even, consistent layer across the attic, between stories, behind walls, or underneath the ground floor.

- Reviewing the entire insulated area, ensuring that every inch of the surface is covered with the right thickness throughout.

It is important to note that this process requires expertise and can be difficult for DIY installations. The use of fire-retardant chemical treatments adds another layer of complexity, making professional assistance the best choice for an effective and safe installation.

Pros and Cons of Cellulose Insulation

Pros of Cellulose Insulation

Cellulose insulation is known for being versatile, affordable, and eco-friendly, making it a great choice for homeowners looking to insulate their existing walls. Unlike other materials, it doesn’t require the walls to be torn down or replaced, which helps save time and effort. If you’re considering insulation, it’s worth taking the time to read and learn about these pros before making a decision.

Perfect for Hard-to-Reach Spaces

If you have an old house with tons of nooks, crannies, and corners, cellulose insulation can be a true lifesaver. The blown-in material can settle into any shape, making it ideal for attics, crawl spaces, and already-finished walls. Since it’s a loose-fill option, it can be applied without the need to remove drywall or do major renovations. Installers simply blow the material through a small hole, typically one inch in diameter, and then seal it after the installation. This allows it to reach awkward areas that batts or rolls cannot. Fortunately, this process ensures a proper fit, maximizing energy efficiency and making your home more comfortable.

High R-Value and Efficiency

Cellulose insulation has a high R-value, making it a powerful and effective choice for thermal protection. With an R-value of around 3.2 to 3.8 per inch, a layer of eight to nine inches can reach about R-30, providing excellent insulation. In comparison, fiberglass requires 12 inches to achieve the same performance. Since blown-in cellulose fills limited space within existing walls, it is a solid option for maximizing energy efficiency.

Eco-Friendly Insulation

If you’re worried about your home’s environmental footprint, installing cellulose insulation is an easy way to make a difference. It is mostly made from 70% to 80% recycled materials, including paper, cardboard, and wood products, which helps reduce waste in landfills and conserve natural resources. In fact, for every ton of cellulose used, an equivalent amount of paper that would otherwise be sent to waste is repurposed.

One of its biggest advantages is its eco-friendliness, as it requires less energy in the production process compared to other types of insulation, like fiberglass and foam. This means lower carbon emissions and a smaller impact on the environment. Additionally, cellulose is biodegradable, so it will not contribute to pollution over time. These factors make it a sustainable choice for homeowners looking for an environmental friendly way to insulate their homes.

Keeps Pests Away

Manufacturers add fire-resistant borates to cellulose insulation, making it a strong defense against pests. These boron-based additives act as good pest and rodent deterrents, helping to keep unwanted creatures out of the home. Fortunately, this feature not only protects the insulation but also provides homeowners with peace of mind, knowing their insulation is resistant to infestations while maintaining its effectiveness.

Effective Soundproofing

Compared to its fiberglass counterpart, cellulose insulation is good at absorbing sound, making it a great choice for reducing unwanted noise. This is particularly true for mid-range frequencies, which covers the range of human speech. Its dense structure makes it very effective in reducing noise inside the home, creating a quieter and more comfortable environment. Often, cellulose insulation has an NRC rating of 0.80 or higher, proving its ability to enhance indoor sound control.

Fire Resistance

If you’re concerned about using paper-based insulation, cellulose is a safe option because it is treated with boric acid and borax to ensure it is fire-resistant. In fact, it is one of the few materials with a Class 1 Fire Rating, which means that in case of a fire, flames will spread slower compared to other insulation types, adding an extra layer of safety to your home.

Energy-efficient

Cellulose insulation is highly energy-efficient and requires less energy to produce than its fiberglass counterpart, with estimates suggesting it takes up to 10 times less energy. Its ability to provide better air sealing makes it an effective choice, as the small fibers fill gaps and crevices, creating a tight seal that prevents air leakage. This maintains a consistent temperature throughout the building, reducing the need for heating and cooling systems to work harder and use more energy.

Additionally, cellulose insulation has a higher R-value, meaning it offers better thermal resistance compared to other types of insulation. This helps keep buildings warmer in the winter and cooler in the summer, making it a cost-effective and eco-friendly choice.

Better Air Sealing

Cellulose insulation has the ability to fill small gaps and crevices, making it a great option for air sealing. It helps with energy efficiency and improves indoor quality by reducing drafts and preventing allergens and pollutants from entering the building. However, a major disadvantage is that improper installation or lack of moisture control can lead to mold growth and reduced effectiveness over time. That’s why it is important to have it professionally installed to ensure proper coverage and avoid any potential issues.

Cost-Effective Solution

Cellulose insulation is an affordable option made from recycled materials, making it a budget-friendly choice for homeowners. On average, its costs range between $0.60 to $2.30 per square foot, which is typically less expensive than other types of insulation. One major advantage of its affordability is that it helps reduce energy expenses without breaking the bank. Moreover, its high density and ability to fill small gaps and crevices result in better efficiency compared to some alternatives, leading to lower utility bills and significant long-term savings for homeowners.

Cons of Cellulose Insulation

Before deciding on cellulose insulation for your home, it’s important to make sure you understand its cons. While professional installation can minimize drawbacks, some disadvantages remain. These often relate to the fact that cellulose is a loose-fill, blown-in material, which may require careful application to ensure proper coverage and long-term effectiveness.

Settling, Wear, and Compression Over Time

While blown-in insulation isn’t a perfect solution for many homes, it is still susceptible to wear, tear, settling, and compression over time. Like all building materials, it will naturally degrade and may need to be replaced when its condition no longer makes it effective. Whether it is sprayed, rolled, or blown-in, gravity causes spaces between particles to decrease. The top layers slowly droop, leading to gaps that can allow cold or warm air to escape. Over time, this reduces the R-value, making the insulation less efficient. In attic spaces, this issue is most common, especially when homeowners step on the material or place objects like holiday boxes, lights, or winter coats on top. The material compresses under pressure, further reducing its thickness and effectiveness.

To combat this issue, installers recommend adding a slightly higher amount of cellulose initially, as it will eventually settle to the desired level. Additionally, regular inspections and maintenance help identify areas where extra insulation might be needed. Since settling can reduce insulation thickness, it is important to have professionals anticipate this problem during installation. A well-planned installation and proper upkeep will ensure that cellulose insulation continues to provide adequate insulation for a longer period.

Moisture Sensitivity and Potential Damage

One major drawback of cellulose insulation is its susceptibility to moisture. Since it is made from paper fibers, it easily soaks up water upon contact and takes a long time to dry. This can lead to mold and mildew problems, making the insulation damp and wet, which in turn lowers its R-value, making it much less effective in preventing air transfer. If exposed to high humidity or leaks, cellulose can absorb excess water, causing growth of harmful microorganisms and reduced insulation effectiveness, potentially affecting the structural integrity of the building.

To mitigate these issues, it is important to ensure proper moisture control measures are in place, especially in areas prone to humidity or leak risks. Installing vapor barriers can protect the insulation from moisture-related damage, and professional inspection is crucial to maintain its long-term performance. If moisture does occur, it must be promptly addressed to prevent further deterioration. In extreme cases, trapped water can cause the insulation to lose its insulating power, and proper installation should address this issue before it becomes a problem.

Challenging Installation Process

Blown-in cellulose insulation requires special machinery, making it difficult for homeowners who prefer DIY projects. It often involves planning, renting a blower, and dealing with a messy installation that leaves behind a lot of dust, requiring a lengthier cleanup process. Unlike other types such as batt or roll insulation, which can be easily placed, cellulose is typically blown or sprayed into walls and spaces using specialized equipment. Since it is not a DIY-friendly option, homeowners will require hiring professionals to ensure the job is done right the first time.

Proper installation is crucial to avoiding issues like settling, moisture damage, and air leaks. That’s why it is important to hire knowledgeable contractors who understand how to install cellulose effectively for long-term performance. Some pros use a wet-spray method, which involves temporarily dampening the insulation to reduce dust and improve application. Additionally, professional installation may be necessary to qualify for manufacturer warranties, which can save homeowners from potential problems and expenses in the future. It’s always best to research and find a reputable company to handle your insulation needs.

How Cellulose Compares to Other Insulation Types

There are different insulation types available for home applications, each with its own benefits. Below is a comparison of cellulose with other common insulation materials:

Blown-in vs. Batt Insulation

- Blown-in cellulose is sprayed into spaces, making it ideal for hard-to-reach areas.

- Batt insulation (also called blanket or roll insulation) is available in pre-cut rolls that installers place between floor joists, trusses, and wall studs.

- Batt insulation comes in standardized widths, making installation easier for homeowners.

Comparison with Other Materials

- Fiberglass is the most commonly used insulation for residential buildings.

- Spray foam is similar to blown-in insulation but uses a liquid product that expands and seals gaps.

- Mineral wool is becoming less common but is still available in batts or loose-fill options.

Each insulation type has its own advantages, and cellulose might not always be the best product choice for every home. Homeowners should consider factors like installation method, effectiveness, and budget before making a decision.

Also Read: Fiberglass vs Cellulose Insulation: Which Saves More?

Is Cellulose the Right Choice for You?

Cellulose insulation offers many benefits, including energy efficiency, cost-effectiveness, and air-sealing capabilities. However, it also comes with some potential drawbacks that homeowners should consider before making a decision. The right choice for your home or building depends on various factors, such as budget, location, and personal preferences. If you are looking for an affordable, eco-friendly option with good insulating properties and air-sealing abilities, cellulose may be a great choice for you.

On the other hand, if you live in an area with high humidity or one that is prone to moisture issues, or if you prefer DIY installation, then other types of insulation may be more suitable. It is important to consult professionals and carefully assess your specific needs before making a decision. The best type of insulation will depend on a combination of factors, so be sure to do thorough research and weigh all the pros and cons before choosing the right insulation for your home.

Final Thoughts

In general, blown-in cellulose insulation works well for existing walls and hard-to-reach places, where fiberglass might not be a viable option. The right choice for insulation varies for each homeowner, as it depends on budget, needs, and long-term goals. A team of experts can evaluate these factors and help you make an informed decision that best suits your home.

Either way, homeowners can expect to recoup the cost of installation within a few years, thanks to the potential energy savings. Over time, this can keep thousands of dollars in your pocket, making it a cost-effective and practical investment.

FAQ

What Are the Negatives of Cellulose Insulation?

Cellulose insulation must be kept dry, as it can absorb water from condensation, air leaks, or home moisture issues. If it gets wet, the material dries very slowly, which can cause it to deteriorate, settle unevenly, and even destroy the chemical fire treatment used for safety. Proper air sealing and moisture control are essential to prevent damage and maintain its effectiveness.

Will Mice Nest in Cellulose Insulation?

The composition of cellulose insulation includes fire retardant chemicals that can irritate rodents like mice. Because of this, they often avoid nesting within cellulose insulation, making it a better choice for homes concerned about pests.

What are the Disadvantages of Cellulose?

Disadvantages:

- Installation costs are often higher compared to other insulation types.

- Creates a massive cloud of dust when installed, requiring a breathing apparatus for safety, especially during large projects.

- Dry-blown cellulose can settle and sag over time, which reduces its R-value, making it less effective.

What Happens If Cellulose Insulation Gets Wet?

If cellulose insulation gets wet and is not dried quickly, it can begin to degrade and grow mold. Unlike spray foam, which is water-resistant, cellulose absorbs moisture and can trap water inside. This can lead to damage in nearby materials like wood wall studs, encouraging rot over time.