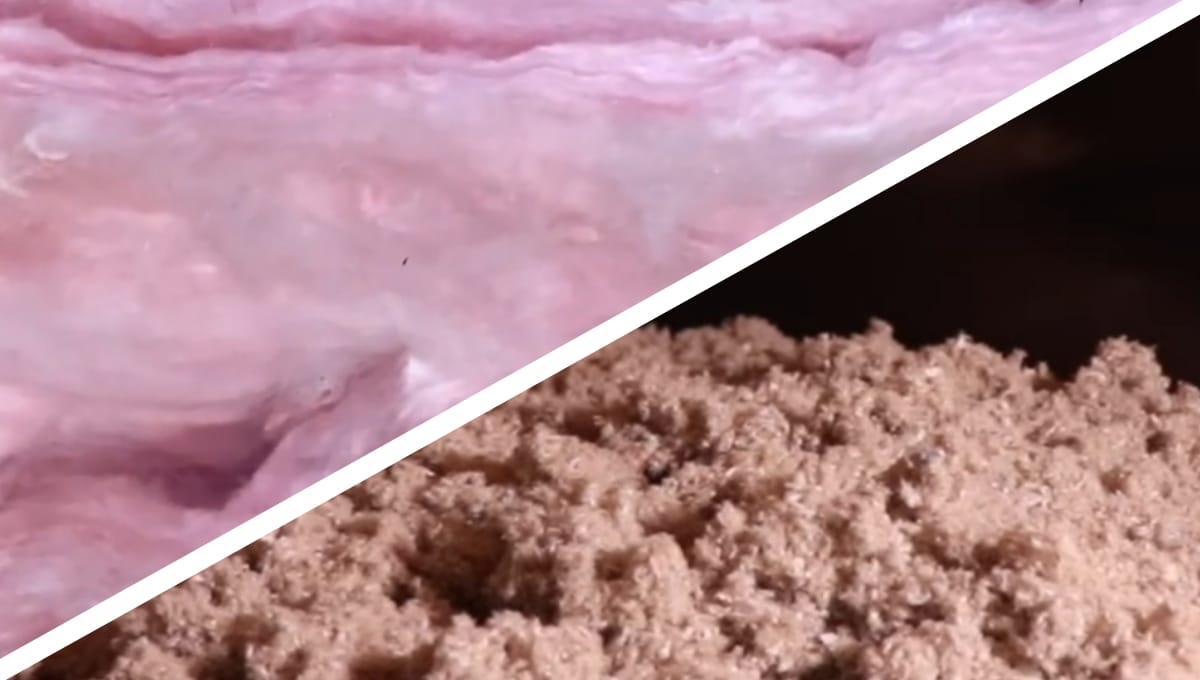

When selecting insulation for your home or business, it’s essential to explore the common types available in the market today. The two leading options—fiberglass and cellulose—each offer unique properties that affect their performance in hot and cold climates. Whether you are considering a remodel or working on a new construction project, understanding these materials’ thermal resistance and efficiency can help you make an informed choice. While fiberglass has long been a popular choice due to its ease of application and affordability, cellulose stands out for being more eco-friendly and offering better effectiveness in varying weather conditions.

Comparing Fiberglass and Cellulose Insulation

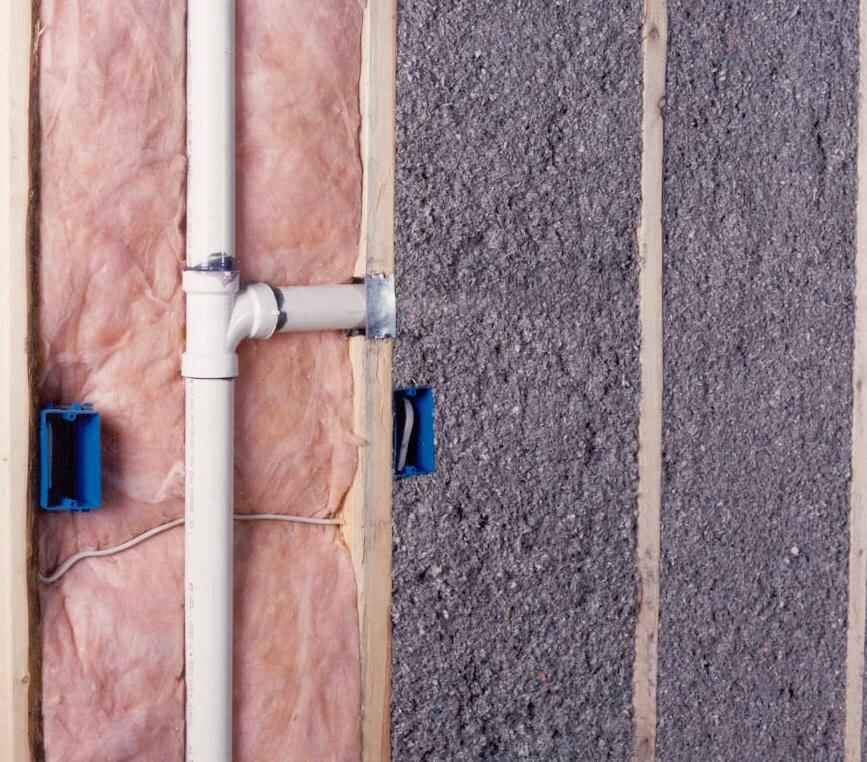

The differences between cellulose vs fiberglass go beyond their material composition. Cellulose is often considered a winner in terms of thermal value, helping keep homes more comfortable by minimizing heat transfer. It’s particularly effective in buildings where energy conservation is a priority. Fiberglass, on the other hand, remains widely used due to its availability and cost-effectiveness, making it an important consideration for those looking to compare insulation options. Both materials play a crucial role in maintaining indoor comfort, and choosing the right one depends on the specific conditions, budget, and energy goals of your home insulation project.

What is Fiberglass Insulation?

Fiberglass insulation is a long-standing choice for homes and buildings because of its durability and thermal efficiency. What fiberglass insulation is best known for is its ability to trap air and reduce heat transfer, thanks to its composition of fine strands of glass woven into a mat. It comes in different forms, including batts, precut sections, blown-in, and loose-fill insulation, making it adaptable for various installation needs. The non-combustible nature of fiberglass enhances fire safety, and it does not settle over time, ensuring consistent performance. However, handling this material requires care as tiny shards can irritate the skin and eyes.

For those looking for an environmentally friendly option, some fiberglass products incorporate recycled, rapidly renewable raw materials. These materials are melted and spun into fibers, forming rolls, loose fill, and blowing wool, which is commonly referred to in the industry. Whether used in walls, attics, or crawl spaces, fiberglass insulation remains a top pick for its affordability, energy efficiency, and long-term reliability.

What is Cellulose Insulation?

Cellulose insulation is an eco-friendly option made from ground-up, recycled newspaper and other paper products. It is primarily used in blown-in form, making it effective for filling attic cavities, existing sidewalls, and hard-to-reach spaces through drill and fill methods. This type of insulation can also be wet-applied, helping it settle into place while reducing air gaps. To improve its fire resistance and pest resistance, it is treated with borate, which enhances its protective properties.

The merits of cellulose insulation lie in its efficiency, sustainability, and performance, which set it apart from other insulation materials. When you compare various areas, cellulose excels in providing better coverage and reducing air leaks. Its ability to retain heat makes it a great choice for those looking for superior energy savings. Whether insulating an attic, sidewalls, or other enclosed spaces, cellulose insulation proves to be a smart investment for comfort and efficiency.

Also Read: 14 Surprising Myths About Cellulose Insulation Debunked!

Cellulose vs Fiberglass: In-Depth Comparison

The Efficiency and Installation of Cellulose and Fiberglass Insulation

When choosing insulation, both cellulose and fiberglass have unique advantages in terms of efficiency and installation. Cellulose insulation is known for its higher R-value, averaging 3.7 per inch, while fiberglass typically ranges from 2.2 to 2.7 per inch. This makes cellulose more effective at reducing heat loss and improving thermal resistance, as its denser structure allows it to fill spaces thoroughly, preventing drafts and maintaining a comfortable indoor temperature year-round. Though fiberglass has a lower R-value, it still provides strong insulation benefits and is widely used in blown-in and loose-fill applications, making it a reliable and cost-effective option.

For those prioritizing energy efficiency and noise reduction, cellulose insulation excels with its impressive soundproofing abilities, helping to create a quieter and more peaceful indoor environment. Fiberglass, with its finer fibers, also helps in reducing outside noise, though its effect can sometimes be overlooked. Both materials are commonly used in wall cavities, 2×4 side walls, and 2×4 construction, with blown-in fiberglass reaching an R-15 rating, while cellulose achieves a maximum R-13.

Impact on the Environment

When considering the environmental impact of insulation, cellulose is often seen as the victor due to its 80-85% recycled materials, mainly newspaper, shredded cardboard, and other paper products. It reduces landfill waste and helps preserve natural resources, making it a planet-friendly choice. The manufacturing process of cellulose insulation is also less energy-intensive than fiberglass, which requires melting sand and glass—a process that consumes significant energy and emits greenhouse gases.

On the other hand, fiberglass insulation contains 20-30% recycled materials and has a lower carbon footprint when compared to some traditional materials. However, its production still involves high-energy use, and it is not as easily removed or reused as cellulose. The offset of energy consumption in transport and installation must also be considered. Both materials have their eco-attributes, but for those who are mindful of sustainability, cellulose insulation offers more benefits in reducing waste and conserving energy.

Longevity and Durability of Fiberglass and Cellulose Insulation

When it comes to longevity and durability, both fiberglass and cellulose insulation offer unique benefits. Fiberglass insulation is highly stable, experiencing virtually no settling and only a 1.5% or less loss in thickness over time, which allows it to maintain thermal performance throughout the life of the building. It is also fire-resistant and does not support pest nesting, making it a reliable option for long-term use. However, it is less resistant to moisture, and when exposed, it can absorb water, which may reduce its R-value and cause compressed insulation over time.

On the other hand, cellulose insulation has a dense structure that helps fill spaces thoroughly, reducing air leaks and improving energy efficiency. It is more resistant to mold and pests due to its borate treatment, which enhances its insulating properties. However, cellulose insulation tends to settle over time, with manufacturers noting a settling rate of about 20 percent in open attics, potentially creating gaps and reducing thermal performance if not installed properly. Choosing between the two materials depends on specific project needs, with fiberglass offering better long-term stability and cellulose excelling in coverage and air resistance.

Installation Process

The installation process for fiberglass and cellulose insulation varies depending on the method used and project requirements. Fiberglass insulation is often the practical choice because of its compression-packed design, allowing manufacturers to store more product in bags, making transportation easier and minimizing storage space. Compared to cellulose, fiberglass requires fewer installers and takes less time, making the job more efficient. Its lightweight nature also allows professionals to complete the installation quickly while reducing waste.

For those opting for fiberglass batts, installation is easier, especially for homeowners who prefer a DIY approach. Batts come in standard widths and lengths, fitting neatly between wall studs and roof joists, though precise cutting and fitting are needed to prevent gaps or voids. Blown-in insulation, whether fiberglass or cellulose, requires special equipment and is best handled by professionals to ensure uniform and thorough coverage. Cellulose insulation, often made from shredded newspaper, tends to be dustier and can settle over time. It is typically dense-packed or wet-sprayed to fill tight corners and crevices, preventing settling and improving insulation performance.

Whether using pre-cut pieces, rolls, or blown-in insulation, both materials have advantages, and the choice depends on project needs and professional expertise.

Differences in Fire Safety

When it comes to fire safety, both fiberglass insulation and cellulose have different properties. Fiberglass is naturally noncombustible because it is made from recycled glass and sand, meaning it requires no additional fire-retardant chemicals. It is available in blown-in, unfaced batts, and other forms, meeting ASTM E136 standards for non-combustible insulation. This makes it a safe option for many buildings where fire hazards are a concern.

Also Read: Is Fiberglass Insulation Flammable? Myths vs. Facts!

On the other hand, cellulose insulation, made from paper products, is combustible and needs to be heavily treated with boric acid and sulfates to protect against fire. Over time, these chemicals may leach, which can lead to health and safety problems. A 1,200 square foot attic insulated to R-38 with cellulose insulation may introduce 300 pounds of fire-retardant chemicals into a home. While both materials offer fire protection, their treatment methods and safety standards differ significantly.

Cost Comparison of Cellulose and Fiberglass Insulation

When choosing insulation, costs play a big role in decision-making. Both fiberglass and cellulose are relatively affordable materials, but their prices vary depending on specific needs, size, and project requirements. Fiberglass is typically cheaper upfront, making it a budget-friendly choice for many homeowners. However, cellulose insulation, with its superior R-value and energy efficiency, can result in long-term savings by lowering energy bills over time.

On average, the price for both materials is similar, costing around $0.70 to $0.80 per square foot for 6 inches of insulation. The final cost depends on several factors, including the shape of the home, the amount and quality of materials needed, and the labor and equipment required for installation. Blown-in cellulose is often more expensive due to its higher density, while fiberglass remains one of the least expensive insulation options available. Whether prioritizing upfront savings or long-term efficiency, homeowners must weigh their budget against insulation performance and durability.

Which Insulation is the Best?

When it comes to insulation, cellulose offers several benefits that significantly outweigh fiberglass. One of the biggest advantages is its higher R-value, meaning it provides better energy efficiency, which can potentially save money on heating and cooling in the long run. Since cellulose insulation is made from recycled materials, it has a lesser impact on the environment compared to fiberglass. It is also fire retardant, insect repellent, and resistant to pests and mold, making it a durable and eco-friendly insulation solution.

Another reason cellulose is a superior option is its soundproofing abilities, which help create a peaceful and quiet indoor environment. The tightly packed material allows less air infiltration, reducing drafts and improving temperature regulation. It is particularly useful in attics, walls, and other intended areas, where it can be blown-in or compressed to stop air flow and provide consistent insulation. However, installation may require professional help, as spraying the material correctly is essential to prevent settling and ensure long-term efficiency.

Despite its slightly higher upfront cost, cellulose insulation undoubtedly provides greater value over time. It is the best bet for homeowners looking to accomplish the same insulation performance as fiberglass but with added benefits like retrofitting houses with improved energy efficiency. Whether planning an attic storage solution, installing wall dams, or insulating cracks and crevices, cellulose is the way to go for an effective, cost-efficient, and sustainable home insulation option.

Final Thoughts

Choosing the right insulation depends on factors like energy efficiency, durability, installation process, and cost. While both fiberglass and cellulose provide effective solutions, cellulose clearly stands out as the better choice. With a higher R-value, it helps reduce energy costs in the long run, while its soundproofing abilities create a peaceful indoor environment. Its fire resistance, pest control, and eco-friendly properties make it a smart investment for homeowners looking for a sustainable and efficient solution. Though cellulose may have a slightly higher upfront cost and require professional installation, its long-term benefits make it the best bet for comfort, safety, and energy savings.

FAQ

What Insulation Is Better, Fiberglass or Cellulose?

Both cellulose and fiberglass are energy-efficient insulation materials, but cellulose has a slight edge due to its higher R-value. It offers approximately 3.2 to 3.8 per inch, while fiberglass typically ranges from 2.2 to 2.7 per inch. This means cellulose provides better heat resistance, making it a great choice for improved insulation and energy savings.

What Are the Downsides of Cellulose Insulation?

While cellulose insulation has many benefits and is a popular choice for homeowners and building owners looking to improve energy efficiency, it also has some potential drawbacks. It can absorb moisture, leading to issues like mold if not properly installed. Settling over time can reduce its effectiveness, and it often requires professional installation to ensure proper coverage and long-term performance.

Why Not to Use Fiberglass Insulation?

Fiberglass insulation is less dense than other types and does not create an airtight seal, allowing air to travel freely through gaps. This air leakage is one of the most common sources of energy loss in a house, reducing overall insulation efficiency and leading to higher heating and cooling costs.

What Type of Blown-In Insulation Is Best?

Fiberglass is one of the most thoroughly tested building materials and can be installed as batt or blown-in insulation. It is eco-friendly, non-flammable, and safe, making it a reliable choice for homes. Additionally, it maintains thermal performance throughout the life of the building, ensuring long-term energy efficiency.