Insulation has a vital role in maintaining a comfortable and energy-efficient home by keeping warmth inside during winter and stopping heat from entering in summer. Understanding the types of insulation is essential for homeowners to make informed choices that suit their needs. Blown-in insulation and batts are the two popular options, made from fiberglass, mineral wool, or cellulose, and are available for various specific needs and structures.

Both types work to minimize heat flow, reduce energy usage, and improve heating and cooling efficiency, helping to lower energy bills and support a sustainable environment. The right choice often depends on your home’s requirements and whether you prioritize proper installation for achieving significant savings.

Key Differences: Blown-In Insulation vs. Batts

Blown-in insulation and batts are two effective options for insulating your home. Blown-in insulation uses a loose-fill material applied with a blower, making it excellent for irregular spaces and hard-to-reach areas. Its ability to fill nooks and crannies provides seamless coverage, enhancing energy efficiency in homes with complex structural designs. This option is often considered budget-friendly for its performance in covering spaces efficiently.

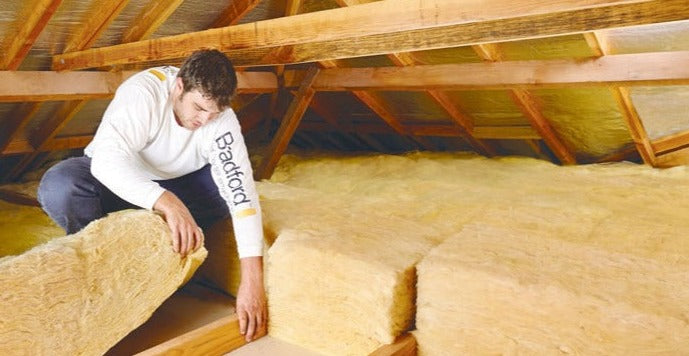

On the other hand, batts insulation comes in pre-cut panels made from fiberglass, rock wool, or cellulose. These panels are placed by hand, making them a user-friendly solution for standard spaces like walls and ceilings. Batts are an economical option and can be quickly cut to fit studs and joists. While they are easier to install in accessible areas, gaps may form if not fitted carefully, which could impact their energy-efficient properties.

| Feature | Blown-In Insulation | Batts Insulation |

| Material | Loose-fill, fiberglass, cellulose | Fiberglass, rock wool, cellulose |

| Application | Applied with a machine | Pre-cut panels placed by hand |

| Coverage | Seamless, fills nooks and crannies | Standard spaces, may leave gaps |

| Energy Efficiency | Higher coverage for irregular spaces | Ideal for standard areas, requires precision |

| Budget | Budget-friendly for unique designs | Economical for standard spaces |

Key Benefits and Application of Blown-In Insulation

Why Blown-In Insulation Stands Out

Blown-in insulation is a preferred option for homeowners who want to make informed decisions. It fills spaces thoroughly, leaving few gaps in attics and hard-to-reach areas. This type of insulation dramatically improves energy efficiency, helping to maintain comfortable temperatures and reduce energy costs.

How Blown-In Insulation Works

Crafted from small particles of fiber, foam, or recycled materials like fiberglass, cellulose, and mineral wool, blown-in insulation is applied using a specialized machine. Professionals direct the material through a large hose into attics, wall cavities, and nooks and crannies, where it expands to create a seamless seal. Its versatility, including options like fire-resistant mineral wool or recycled paper cellulose, makes it suitable for a variety of needs and enhances safety and performance.

Pros of Blown-In Insulation

- Effective at filling gaps, especially in irregular spaces and oddly shaped areas.

- Offers high energy efficiency, making it a good choice for insulation.

- Quick installation using a machine, ensuring ease and seamless coverage.

- Made from mainly recycled materials like cellulose, fiberglass, newspaper, glass, and mineral wool, making it better for the environment.

- Ideal for insulating tight areas, with materials designed to fit snugly and reduce heat loss.

- Treated with borate, which makes it fire retardant, preventing char, redden, and spread of flames.

- Resists pests, mold, and dampness, ensuring long-term durability.

- Has an R-value of 2.2 to 3.8 per inch, providing effective insulation for most applications.

Cons of Blown-In Insulation

- Costly compared to batts, making it a more expensive option upfront.

- Requires professional installation, needing a skilled team with the appropriate equipment for the job.

- Possible settling over time, which can reduce the R-value and compromise its performance.

- Can become messy and retain water if exposed to moisture, leading to issues like mold and a long drying process.

- Treated with borate for preventing pests and vermin, but this can affect its eco-friendly status due to chemical treatment.

- Best suited for attics, but improper application could diminish its benefits.

- Claims of being eco-friendly are often diminished by the presence of chemicals that reduce sustainability.

Understanding Batts Insulation

Material Choices and Installation

Batts insulation is a popular option for homes, known for its simplicity and cost-effectiveness. It comes in rolls or pre-cut panels, made from materials such as fiberglass, mineral wool, or cotton. Each material offers distinct benefits, including being fire-resistant, offering soundproofing, and being eco-friendly. For those seeking more sustainable solutions, cotton batts are a natural and less itchy choice. Polyester batts are another great option, offering a non-toxic and eco-friendly alternative. Made from recycled polyester fibers, they provide excellent thermal performance while being safe to handle without irritation.

The installation of batts is straightforward as they fit neatly between studs, joists, or beams. Ensuring proper fitting is crucial to avoid gaps that could reduce effectiveness. Their inexpensive and widely available nature makes them ideal for various projects, but maintaining a snug fit is key to preserving efficiency and overall performance.

Pros of Batt Insulation

- Batt insulation is readily available and easy to get without much wait time.

- It can be installed in almost any area of a home, including attics, walls, and flooring, ensuring wide usability.

- Inexpensive to install, it is one of the least expensive options for insulation.

- Simple to handle, making it a cost-effective and good choice for DIY projects.

Cons of Batt Insulation

- Batt insulation has a lower R-value, typically around 2.9 to 3.8 per square inch, requiring you to stack multiple layers to achieve the proper amount of insulation.

- It can be difficult to install in oddly shaped areas due to its pre-cut size, which might not fully cover the product and leave gaps, reducing efficiency.

- Susceptible to moisture damage, fiberglass batts can become wet and lose their insulating ability until it dries completely.

- Over time, batts may compress, further reducing their performance. Additionally, the material can be itchy and may irritate the skin during installation.

Comparing Blown-In and Batts Insulation

Blown-in insulation and batts are two popular methods for keeping your home warm and cozy. When considering energy efficiency, blown-in insulation stands out for its ability to reduce air leakage by sealing gaps effectively, while batts require careful installation to achieve similar results. A detailed comparison shows that blown-in generally offers a higher R-value and better performance in irregular spaces. However, batts remain a reliable choice for standard areas where precision fitting is simpler, making it the right insulation depending on the home’s specific needs.

Cost Analysis

Fiberglass Batts Cost

Fiberglass batts are one of the most advertised options. They come in different R-value ratings like R-15, R-19, and R-38, and their cost varies by application, geography, and square foot coverage. A quick search on a home improvement website shows that prices generally range from $0.60 to $2.50 per square foot, with some batting options being more expensive due to kraft facings or unfaced variations. The impact of vapor barriers also affects the price, and skipping retarders can cut costs but may reduce effectiveness in handling moisture content and preventing molding.

Blown-In Fiberglass Cost

Blown-in fiberglass insulation is sold in bags, usually weighing approximately 28 pounds each. The total cost depends on the R-value required for the project and the square foot coverage. For applications requiring R-19 or higher, you may need over 100 pounds, which makes it a more expensive option. The advertised price for blown-in insulation typically ranges from $2.50 to $4.00 per square foot, but this doesn’t include the blower rental fee, which can be $200 per day. Renting a blowing machine is necessary to disperse the particles, and some machines require purchasing specific brands of bags, so it’s essential to check the requirements before purchasing bags.

Long-Term Savings

Insulation plays a major role in making a long-term decision that impacts energy bills.

- Blown-in insulation offers better coverage by reducing energy loss, which translates to savings over time.

- By filling nooks and reducing heat escape, it leads to lower monthly bills and makes the investment pay off in a few years.

- Batts insulation, however, can leave gaps, causing heat to escape and potentially leading to higher costs if it is installed incorrectly.

Both types help with heating and cooling, but choosing the right option ensures fewer adjustments are needed in the future.

Ease of Installation

When it comes to installation, blown-in insulation vs batts each offer unique advantages, but their ease of use depends on your project needs. Batts insulation is a simple option for homeowners looking for a DIY-friendly solution. Made from fiberglass, rock wool, or other materials, batts come in pre-cut panels that fit neatly between standard studs and joists, making them ideal for structured spaces like walls and ceilings. However, proper placement is essential to avoid gaps that could reduce efficiency.

On the other hand, blown-in insulation requires a more complicated installation process but offers flexibility that batts cannot match. Using a specialized machine, professionals spray loose-fill materials like fiberglass or cellulose into walls, attics, and hard-to-reach spaces. This method is ideal for irregular spaces or areas with obstructions, as the material conforms to gaps for even coverage. While homeowners might consider doing it themselves, blown-in insulation requires rentals of equipment like a blower and comes with risks, such as handling tiny shards of glass or other particles. Investing in PPE, such as gloves, eye protection, and a mask, is crucial for safety.

For larger projects, many homeowners prefer hiring professionals to handle the task, ensuring optimal performance and reducing risks. Selecting the right insulation type depends on whether you prioritize the key factor of simplicity or the superior coverage that blown-in offers.

Installation Time and Labor: Blown-In vs. Batts

When considering time and labor, both blown-in insulation and batts have unique advantages depending on the project’s needs. Blown-in insulation is faster for complex areas because of its adaptable nature. However, the installation process requires a machine, an operator, and often two people—one to feed the material into the blower and another to operate the hose. This type of installation works best for large-scale or time-sensitive projects, but the added labor intensity and equipment needs should be considered.

Batts insulation, on the other hand, is quicker for straightforward layouts like walls and ceilings. It involves less equipment and can be a manageable DIY project for a single person, though more time might be needed for spaces with cuts or obstacles. Homeowners must weigh the pros and cons of each option, considering their personal skills, the complexity of their space, and timelines to make an informed decision.

| Feature | Blown-In Insulation | Batts Insulation |

| Time | Faster for complex areas |

Quicker for straightforward layouts |

|

Labor Intensity |

Requires two people, machine |

Single person, less effort needed |

| Equipment |

Needs blower, hose |

Minimal tools |

Comparing Fiberglass Insulation Performance: Blown-In vs. Batts

Fiberglass insulations, whether blown-in or batts, are widely used for their affordability and effectiveness in reducing heat loss. Both types are also effective at dampening sound transfer, making them useful for noise control in homes. However, each has unique advantages and drawbacks, which are worth exploring in detail.

Fiberglass Batts Performance

Fiberglass batts are considered one of the lowest-performing insulation products available, primarily due to their premanufactured shape, which can cause gaps during installation. For example, a 16-inch batt may not fully fill a 17-inch cavity, leaving empty spaces that limit the insulation’s maximum performance. While batts are inexpensive and convenient to install, they allow air to pass through, leading to conductive heat transfer and potential issues with airflow infiltration. This means allergens, dust, and moisture can travel through the insulation, reducing its overall efficiency compared to more expensive options like spray foam.

Blown-In Fiberglass Performance

On the other hand, blown-in fiberglass is a higher-performing insulation option. Its loose-fill product design allows it to conform to unique spaces and crevices, solving many of the gapping problems associated with batts. Although blown-in fiberglass is a lighter product, it can still effectively fill spaces, though it lacks air-sealing technology and allows air to infiltrate, which can reduce its insulating potential. Alternatives like heavier cellulose blown-in insulation offer even higher performance due to their weight and density, but the fluffier texture of fiberglass still makes it a practical choice for homes needing a more flexible solution.

Health Implications of Insulation

Both blown-in and batts insulation have potential health effects. Fiberglass batts may irritate the skin or lungs during installation, but using good practices like wearing proper safety gear can minimize the risk. Blown-in insulation, especially cellulose, contains fewer chemicals, making it safer for indoor air. However, ensuring proper installation is key to avoid health issues and to keep your home’s air safe.

Health Considerations for Blown-In and Batts Insulation

- Blown-in insulation contains fewer chemicals, particularly in options like cellulose, making it safer for indoor air.

- Fiberglass batts may irritate the skin and lungs during installation, especially without proper safety gear.

- Good practices, such as using protective equipment like gloves, masks, and goggles, can minimize health risks for both types of insulation.

- Proper installation is essential for both options to prevent health issues and maintain a safe environment inside your home.

- Handling airborne particles during installation requires careful management, especially with blown-in insulation, to ensure safety.

Air Quality Control in Homes

Controlling air quality indoors is essential, and the type of insulation you choose has a direct impact. Blown-in insulation is known for its superior ability to seal gaps, reducing outdoor air infiltration. However, it can release more particles during installation, which requires careful handling. Batts insulation, while easier to install in standard spaces, relies heavily on precise fitting to maintain efficiency.

| Feature | Comparison |

| Air Sealing |

Blown-in excels at filling gaps and openings, while batts require precision. |

| Airborne Particles |

Blown-in may release more particles during installation; batts release fewer. |

| Efficiency | Blown-in effectively reduces outdoor air and pollution; batts risk inefficiency if not fitted well. |

| Maintenance | Blown-in requires minimal upkeep once installed; batts need regular checking and refitting. |

Choosing the right insulation depends on your home’s needs. For better air quality and fewer drafts, blown-in insulation might be the better choice, but batts insulation can also perform well with proper fitting and maintenance.

Durability And Longevity

When choosing the right insulation for your home, considering its durability and longevity is essential. Both blown-in insulation and batts serve their purpose well but differ significantly in their lifespan and ongoing maintenance requirements. The type of material used and the efforts made to maintain it determine how well the insulation will keep performing over time.

Fiberglass Batts Longevity

Fiberglass batts are often advertised with a potential lifespan of a century if left undisturbed and free from external variables. However, in real-world applications, they typically begin to deteriorate within fifteen to twenty years. Over time, they can sag, creating gaps that compromise performance. Additionally, dust, mold growth, or moisture infiltration in the installation area can further reduce their effectiveness and lifespan.

Blown-In Fiberglass Longevity

Blown-in fiberglass, on the other hand, provides more flexibility but still needs to be checked every fifteen to twenty years. Unlike batts, it does not face issues like sagging, but it can settle over time, requiring additional insulation to be installed on top. Maintaining consistent performance levels means calculating the required R-value and monitoring the settled depth. Homeowners may also need to rent a blower machine to refresh and top off the insulation, ensuring it continues to provide adequate coverage.

Maintenance and Upkeep: Keeping Insulation Effective

Regular maintenance and upkeep are key to maximizing performance and ensuring the lifespan of your insulation. Blown-in insulation requires frequent inspection to check for settling, compaction, and even distribution. It is also crucial to seal leaks and avoid water infiltration, as moisture can compromise its effectiveness. In contrast, batts insulation needs to be tightly fitted between studs, with damaged or wet sections replaced promptly. Proper care prevents displacement during attic activities and ensures consistent performance over time. Both types benefit from attention after repairs or renovations to maintain their insulating properties.

| Feature | Blown-In Insulation | Batts Insulation |

| Inspection Needs |

Check for settling and distribution |

Ensure tight fit, check for gaps |

|

Moisture Management |

Seal leaks, prevent water infiltration | Replace wet sections |

|

Maintenance Frequency |

Frequent checks for redistribution |

Regular attention to displacement |

| Special Care | Adjust after renovations | Prevent shifts during attic activities |

Environmental Considerations: Choosing Sustainable Insulation

Making environmental considerations is key when choosing the right insulation for your home. Both blown-in insulation and batts impact sustainability, and understanding their recycled content and eco-friendly options helps homeowners make a responsible choice. Insulation not only improves home comfort but also contributes to protecting the planet by reducing energy consumption and waste.

Sustainability Factors

Sustainability is essential for the future, and insulation helps in reducing energy consumption in homes.

- Blown-in insulation has a long lifespan, requiring fewer replacements and generating less waste over time.

- Batts insulation is easier to replace in sections, making it more flexible for specific areas, but it may result in more frequent material use.

- Both types contribute to energy savings, helping homeowners lower energy bills and reduce greenhouse gas emissions, improving overall efficiency.

Recycled Content and Eco-Friendly Options

The recycled content of insulation makes a big difference for the Earth. Blown-in insulation is often made with up to 80% recycled materials, usually newspaper, and offers diverse low-impact options like fiberglass alternatives. Batts insulation can also include some recycled content, though generally less. For homeowners seeking sustainable choices, natural fibers such as cotton batts are excellent alternatives. Assessing these options is pivotal to finding the most eco-friendly materials, with blown-in insulation often leading the race, though batts remain a worthy competitor.

|

Feature |

Blown-In Insulation |

Batts Insulation |

|

Recycled Content |

Made with up to 80% recycled materials |

May contain some recycled content |

|

Eco-Friendly Materials |

Includes low-impact alternatives |

Includes natural fibers like cotton |

|

Lifespan |

Long-lasting, reducing waste over time |

Easier to replace in sections |

|

Sustainability Impact |

Reduces energy consumption and waste |

Saves energy but requires more replacements |

Decision-Making Guide: Blown-In vs. Batts Insulation

Starting a home insulation project is a crucial decision for improving comfort and achieving energy savings. This guide helps homeowners navigate between blown-in insulation and batts, offering vital information to make an informed choice. Tailoring your decision to your unique needs ensures the best results for your home and budget.

Assessing Your Needs

Understanding the specifics of your project is key to choose the right material.

- Space constraints are important—blown-in insulation works well in tight spots, while batts require larger access points.

- Installation complexities vary—blown-in insulation often needs professional gear, while batts are a more DIY-friendly option.

- Consider time and budget—batts are usually more cost-effective, but blown-in insulation can offer better long-term energy savings.

Making the Energy-Efficient Choice

|

Feature |

Blown-In Insulation |

Batts Insulation |

|

Coverage |

Complete, reduces thermal bridging |

May leave gaps if not installed meticulously |

|

R-Value (Thermal Resistance) |

Higher per inch, offers better efficiency |

Varies by material, generally lower |

|

Durability |

Long-lasting, resists settling |

Can sag over time, reducing effectiveness |

| Efficiency |

Maximizes energy efficiency with superior thermal barrier |

Cost-effective in specific situations |

|

Cost |

Higher upfront cost, better long-term savings |

Lower upfront cost, less effective for long-term efficiency |

When deciding, weigh your personal preferences, specific requirements, and the balance between investment and savings. Blown-in insulation provides a superior thermal barrier, while batts insulation is more suited to cost-sensitive situations.

When Should You Use Fiberglass Insulation?

The best application for fiberglass insulation is for interior walls, where batts can be used to reduce sound transfer between rooms. While batts insulation often creates gaps that may compromise insulating value, these spaces don’t require seamless applications like exterior walls do. This makes fiberglass batts an inexpensive solution for controlling noise and maintaining moderate insulation in your home.

For attics, blown-in insulation is usually the better choice, but it comes with a caveat. It should be paired with an air-sealing product to boost performance and prevent the flow of air and heat. If you’re considering adding blown-in insulation to your existing attic insulation, it’s worth removing the old material first to ensure better overall efficiency.

When Fiberglass Insulation Isn’t the Best Choice

It’s not recommended to use fiberglass insulation for exterior walls or basements due to its lower-performing nature and lack of air-sealing capabilities. For exterior walls, performance is crucial as they act as a barrier between the outside temperatures and your home’s conditioned temperature.

Fiberglass should never be used in below-grade applications like basements because it lacks a proper vapor barrier. While kraft facings can act as retarders, these are not sufficient for areas with high moisture content, which necessitate more effective solutions like closed-cell spray foam. This ensures the insulation performs effectively without the risk of water damage.

Final Thoughts on Choosing the Right Insulation

Choosing the right insulation for your home is crucial to ensure comfort and efficiency. Both blown-in and batts have unique advantages, tailored to various needs. While these are not always high-performance products, they are options many homeowners can install themselves. The best uses include interior walls and attics treated with air-sealing products, providing effective results within their performance limitations. For other project categories, we recommend exploring insulation options that might involve a premium product, which, while initially more expensive, could help save energy bills over the lifetime of the building.

FAQ

What Is Better, Batts or Blown-In Insulation?

Blown-in insulation is often seen as a more effective thermal barrier, but its effectiveness might be temporary and may not last for the life of the building. Batts, however, provide reliable performance and are a practical option for long-term use.

What Are the Disadvantages of Blown-In Insulation?

One of the main disadvantages of blown-in insulation is its sensitivity to moisture. If your attic has a water problem or leaks, the insulation can become damp, leading to mold growth and reduced effectiveness. Additionally, blown-in insulation requires professional installation, as it may seem simple but needs to be handled by experienced professionals for the best results.

What Type of Insulation Is Best for an Attic?

The best type of insulation for an attic depends on your needs. Cellulose is a highly eco-friendly and cost-effective option for attics, while fiberglass and mineral wool are popular choices. These materials are great at keeping heat in or out and can also resist moisture and pests effectively.

What Are the Disadvantages of Batt Insulation?

One of the main disadvantages of batt insulation is that fiberglass batts are not resistant to moisture, making them prone to mold and mildew. This can be a significant concern in areas with high humidity or potential water leaks, as it affects their performance and durability.