For contractors and applicators, selecting the right insulation is a critical role in ensuring energy efficiency, comfort, and cost-effectiveness for homes and businesses. Many homeowners aren’t fully aware of insulation options or which one suits their project best. Cellulose insulation vs spray foam is a common debate, as both materials offer unique benefits for residential and commercial situations. While cellulose insulation is a popular choice due to its affordability and eco-friendly properties, spray foam is known for its superior energy efficiency and sealing abilities. Understanding the key differences between these materials will help educate clients and allow them to choose the right solution for their home, particularly in extreme weather conditions like summer and winter.

Both foam insulation and cellulose insulation help keep a home warm in winter and cool during the summer, but they function differently. Cellulose insulation, made from recycled paper, offers sufficient thermal resistance but isn’t as airtight as spray foam, making it less effective at sealing gaps. Spray foam expands to fill spaces correctly, preventing air leaks and improving indoor temperature stability. Factors like cost-effectiveness, climate, and structure type influence which option is the better fit. By understanding these significant differences, professionals can help clients decide where and when each option works best.

Key Differences Between Spray Foam and Cellulose Insulation

Understanding Composition and Installation

Spray Foam Insulation

When it comes to spray foam insulation, it is made from a combination of chemicals like isocyanate and polyol resin. It is applied as a liquid and then expands into foam, forming an airtight seal that fills gaps. This makes it ideal for irregular or hard-to-reach spaces. It comes in two types: open-cell and closed-cell, each offering different levels of insulation and air-sealing properties. Because of its structure, spray foam provides superior insulation but requires professional installation due to the precision needed for proper application.

Cellulose Insulation

On the other hand, cellulose insulation is composed primarily of recycled paper products and is treated with fire retardants for added safety. It is typically blown into walls, attics, and other spaces, making it a highly efficient, non-toxic insulation material. Made from 85% newspaper, it contains more than double the recycled content of any other type of insulation. Because it is loose-fill, cellulose settles into cavities easily, offering good coverage with minimal air pockets, though it may require periodic maintenance to prevent compaction.

Comparing Efficiency: R-Value of Spray Foam Insulation vs. Cellulose

When it comes to insulation efficiency, R-value is a key metric that refers to the resistance of heat transfer between hot air and cold air. The higher the number, the more thermal-resistant the insulation material, meaning it effectively insulates a space. Spray foam excels in this area, especially closed-cell foam, which boasts an R-value of R-6.5 to R-7 per inch. Open-cell foam offers a lower R-value, at about R-4, but still provides strong insulation and air sealing.

On the other hand, cellulose insulation has an R-value of around 3.2 to 3.8, with an average of 3.5 to 3.7 per inch. While their R-values are similar in some cases, spray foam’s sealing capabilities give it an advantage, especially in extreme climates where insulation performance matters most. Cellulose insulation is a decent option, but it is still not as high in efficiency as spray foam.

Depending on density and application method, spray foam remains the better choice for maximum energy savings and climate control.

Comparing Air Sealing: Spray Foam Insulation vs. Cellulose

For homeowners looking for an air seal, spray foam is often the top choice. Companies claim that closed-cell foam provides a permanent barrier against air movement, helping insulate the house effectively. While this is true for a short while after installation, it may not always last. Over time, factors like temperature, humidity, and foam shrinkage can affect its performance. As the material contracts and expands, shrinkage can lead to gaps, reducing effectiveness and causing significant heat loss in winter and an inability to keep out hot air in summer. If not applied correctly, spray foam may even crack, creating areas where air moves through the layer, allowing convection to take place.

However, when installed properly, high-quality spray foam acts as an effective air barrier, serves as a moisture barrier, and reduces the risk of mold and mildew, making it a key selling point for clients concerned about indoor air quality and structural integrity, especially in attics and basements.

On the other hand, cellulose insulation is not intended to act as an air seal, but it still reduces airflow by slowing the movement of air. When applied to an exterior wall, it is often used in conjunction with a sealing membrane to create a highly effective air blocker. Dense-pack and sprayed cellulose are designed to fit correctly throughout a house, forming an airtight layer that helps prevent conduction and convection. The end result is a long-lasting, energy-efficient, and quiet home.

While spray foam excels at sealing air leaks, cellulose insulation provides good coverage and resistance to airflow, making it an option for those prioritizing sustainability over complete air sealing. However, it doesn’t mix well with water and may develop mold or mildew in damp areas, requiring careful installation and maintenance.

Comparing Soundproofing: Spray Foam Insulation vs. Cellulose

When choosing insulation, controlling external noise and internal noise is just as important as maintaining a comfortable temperature. The ability to reduce noise levels depends on the Sound Transmission Class (STC), a measurement of how many decibels are absorbed as sound passes through the material. A higher STC number means better sound insulation quality.

Closed-cell spray foam, a dense material, is better at deflecting sound rather than absorbing it, with an STC of around 39.

In contrast, cellulose insulation, made of loose fibers, is better at absorbing sound and can be densely applied, achieving an STC between 44 and 68. This makes cellulose insulation a great soundproofing option for a quieter home, especially when compared to closed-cell spray foam.

Comparing Longevity: Spray Foam Insulation vs. Cellulose

According to experts in home performance, spray foam insulation is highly durable and does not degrade over time. It often lasts more than 30 years and provides excellent insulation, making it a long-term investment for homes. The rigid structure of closed-cell foam helps add strength to buildings and resists settling and degradation. However, it is vulnerable to damage from impact and scratches, so caution is advised when using it in spaces with children or pets. Additionally, spray foam insulation contains chemicals that can be hazardous if not handled properly.

On the other hand, chemically-treated cellulose insulation can last between 20 years but behaves differently when it gets wet. The insulation may be affected, losing its ability to resist mold if exposed to excess water. While it may still perform if only some parts are wet, if soaked, a lot of the material may need to be replaced completely. Cellulose insulation is known for its durability but is also prone to settling, which can reduce R-value and insulating performance. This common issue can create gaps, making regular checks and maintenance key in mitigating the problem.

Cost Comparison: Spray Foam Insulation vs. Cellulose

When it comes to insulation costs, spray foam is generally more expensive upfront due to the materials, specialized equipment, and professional installation required. The cost of spray foam insulation varies between $0.25 and $3 per board foot, depending on the type. Installers measure it by one-inch thickness per board foot, so for most walls, which are 3.5” thick, the total cost increases. Though spray foam costs 50% to 70% more than cellulose insulation, it offers significant long-term savings on energy bills by sealing gaps effectively.

On the other hand, cellulose insulation is less expensive initially and can be installed by a team or clients themselves, making it a budget-friendly option for many projects. The cost of blown-in cellulose insulation typically falls between $1.0 and $2.80 per square foot, making it a cost-effective choice. For a 1,500-square-foot house, cellulose insulation can cost between $2,500 and $5,000, while spray foam insulation for the same area ranges between $5,000 and $10,000. However, cellulose may require maintenance and upkeep over time, which could reduce long-term cost savings. Choosing between these options depends on budget, insulation needs, and future energy savings.

Ease of Installation: Spray Foam Insulation vs. Cellulose

Installing insulation can be a challenge, especially when choosing between foam and cellulose insulation. Spray foam requires specialized equipment and training, making it difficult to apply on your own. It’s not an easy job and usually needs professionals due to the installation complexity and careful application required. The unique process makes it more expensive, adding to labor costs. If done improperly, it can lead to potential health risks, reinforcing the need for a professional approach.

On the other hand, blown-in cellulose insulation is a simpler and quicker method that allows the material to fill the smallest gaps and crevices, ensuring a well-insulated attic. It is also a DIY project with proper planning and knowledge, as you can rent a motorized hopper to install it yourself, saving money on labor.

For homeowners alike, cellulose insulation wins the battle, as it does not require technical expertise like spray foam, which has a longer curing time and a more careful application process.

Comparing Safety: Environmental and Fire Protection of Spray Foam vs. Cellulose

Cellulose insulation is made from recycled paper and is one of the greenest choices for insulation. It contains treated chemicals that make it fire-resistant and help prevent mold growth and insects. Because it is made from green materials, many consider it to be the best option for those looking for environmental friendliness. However, if not installed correctly, leaks and exposure to moisture can react with the chemicals, leading to harmful fumes. While borate compounds are non-toxic, prolonged water exposure may reduce their effectiveness, requiring maintenance or replacement.

On the other hand, spray foam insulation, especially closed-cell, is a petroleum-based compound and is considered highly toxic. Some companies convince homeowners that once foam is cured, it is totally safe, but the hazards are more complicated. The material releases isocyanates, which can cause asthma, allergic reactions, and other irritants. The EPA acknowledges that the off-gassing of these volatile chemicals is not fully understood. Additionally, spray foam insulation is highly flammable, though installing a thermal-resistant barrier can help prevent fires.

While spray foam offers more moisture resistance, it lacks fire resistance compared to cellulose insulation, making comparison essential when deciding between the two materials.

Installation Process: How Are They Installed?

Blown-In Cellulose Insulation

The installation of blown-in cellulose insulation begins with preparing the area, which involves sealing air leaks in the attic, installing vent chutes, and setting up an insulation dam. Next, the material is loaded into a specialized machine, which breaks it apart before it is blown through a long hose. The installer moves around, evenly distributing the insulation to the desired depth. The entire process can be completed within a day, depending on the size of the attic.

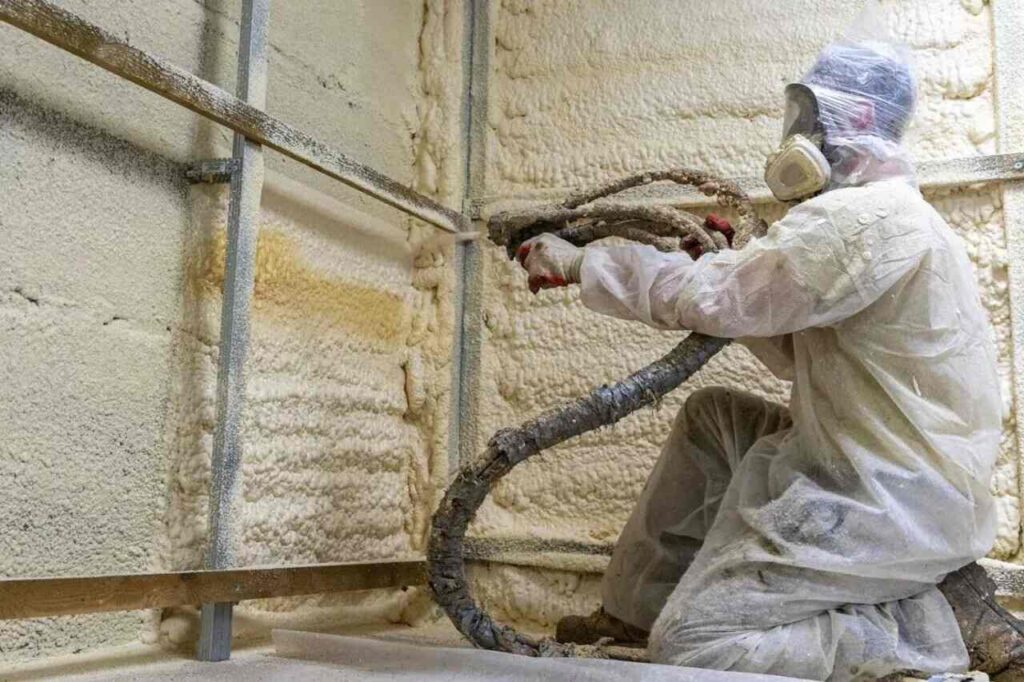

Spray Foam Insulation

The installation of spray foam insulation is more complex and starts with preparing the area. This includes covering items in the attic that need protection from overspray. Using a specialized sprayer, the liquid foam is sprayed onto the desired surfaces, where it expands and hardens, forming a solid, continuous layer of insulation. The foam must then be allowed to cure, a process that takes up to 24 hours. After curing, the foam is trimmed and covered with a fire-protective layer, if required. Due to the technical nature of the process and the potential risks of mishandling materials, it is crucial to hire professionals for the best results.

Choosing the Best Insulation for Your Home

When deciding between blown-in cellulose and spray foam insulation, there are several factors to consider before making the right choice. Your budget, energy efficiency goals, environmental considerations, and whether you have existing insulation all play a role in determining which material is best for your home. Both options have their benefits, but the ideal choice depends on your specific needs.

Budget

If you’re working with a limited budget, blown-in cellulose is the better option due to its lower installation cost. It provides effective insulation at a more affordable price, making it a great solution for cost-conscious homeowners.

Energy Efficiency

For those prioritizing energy efficiency, spray foam—particularly closed-cell—offers the highest possible insulation performance. It seals gaps and prevents air leaks, leading to improved indoor temperature control and long-term energy savings.

Environmental Considerations

If sustainability is a concern, environmental considerations should be factored in. Cellulose is the greener choice as it is made from recycled materials and is more eco-friendly compared to spray foam, which is petroleum-based.

Existing Insulation

If you already have existing insulation in your attic and just need to top up, blown-in cellulose is a great choice. It can be added without major renovations, providing an easy and effective way to improve your home’s insulation.

When to Choose Cellulose vs. Spray Foam Insulation

To make the right choice, homeowners must understand the key characteristics of both types of insulation. The decision depends on the project at hand, including factors like energy efficiency, moisture resistance, and air sealing. Now is the time to determine which material is best suited for specific applications.

Best Uses for Spray Foam

Spray foam insulation is ideal for a variety of residential, industrial, and commercial facilities. It is particularly useful in potentially damp areas like basements, attics, sheds, and RVs. Its applications extend beyond just insulation, as it provides numerous opportunities to support customers and grow business in new ways.

Energy Efficiency and Long-Term Savings

For customers looking to achieve the highest possible energy efficiency, spray foam is the way to go. It ensures long-term savings and is ideal for those who plan to live in their home for the long-term, especially in extreme climates.

Protecting Against Moisture

When insulating basements, crawl spaces, attics, and other areas, moisture control is essential. Spray foam is the best choice to provide the most moisture protection, keeping spaces dry and resistant to water damage.

Insulation with Air Sealing

If customers need insulation that also provides air sealing, spray foam offers a comprehensive solution. It fills gaps effectively, preventing air leaks and improving overall building performance.

Cellulose Insulation

For a Budget-Friendly Option

If cost is a primary concern, cellulose insulation is a smart choice because it offers good performance at a lower initial price point. While it provides strong insulation, homeowners should consider its durability and longevity since replacement costs can add up in the long run. Despite this, it remains an affordable option for those looking for reliable insulation without high upfront expenses.

For Eco-Friendly Projects

For homeowners prioritizing sustainability, cellulose is an attractive choice because it is made from recycled materials. While it is considered an eco-friendly option, it still uses some chemicals to flame-proof the material, ensuring safety without compromising insulation performance.

Fire Protection

When fire protection and resistance are top priorities, especially in areas like kitchens, blown-in cellulose insulation is a good option. It undergoes chemical treatment to minimize flammability, offering an added layer of safety in fire-prone environments.

Retrofitting Interior Projects

For existing interior structures, cellulose is a great option as it can remain dry and be blown into wall cavities without major renovations. This makes it a practical choice for improving insulation in older homes or spaces that need an upgrade without extensive remodeling.

Final Thoughts

Both cellulose insulation and spray foam have their strengths, and the best choice depends on specific needs. For those on a budget, cellulose insulation is a cost-effective option that still provides good performance. It is also an eco-friendly choice, made from recycled materials, though it requires maintenance over time. On the other hand, spray foam insulation excels in energy efficiency, moisture control, and air sealing, making it ideal for long-term benefits in residential and commercial settings. By understanding key differences and considering factors like budget, energy efficiency, and application needs, homeowners can make an informed decision that best suits their home.

FAQ

Is Blown-In Cellulose Insulation Better Than Spray Foam?

When it comes to performance, spray foam insulation exceeds cellulose in R-value per inch, making it more effective at sealing air leaks. However, cellulose is cheaper and a good alternative for cost-conscious homeowners. While open-cell and closed-cell foams are more expensive, they offer superior insulation. Fiberglass is another option that performs well, is durable, and is simple to install, but it lacks the air-sealing benefits of spray foam.

What is the Downside of Cellulose Insulation?

Cellulose insulation is heavy and can compact underlying insulation, reducing its effectiveness. Since it is made from paper, it absorbs moisture during rains or in areas with high humidity. Over time, it degrades and may need to be replaced. It also promotes the growth of mold and mildew, especially in the attic, if not properly installed or maintained.

Why is Spray Foam a Red Flag for Lenders?

Spray foam insulation can be a red flag for lenders because it affects crucial metrics that mortgage lenders consider. Insulation matters when evaluating a home’s saleable value and energy efficiency rating. Poor installation or difficulty in future modifications may cause lenders to throw up concerns, impacting mortgage approval.

Why Are People Removing Spray Foam?

When spray foam insulation is incorrectly installed or used inappropriately, it can reduce air circulation and ventilation in the roof space. This can lead to dampness and condensation on the underside of the roof, as it forms an air barrier that stops moisture from escaping. In some cases, this may place timber-framed roofs at risk of decay, leading homeowners to remove the insulation.