Installing spray foam insulation can be a premier solution for making your home more energy-efficient by reducing heat loss and improving heating and powering systems. It offers a variety of benefits, including cost savings and environmental impact reduction. Taking the DIY route may seem like a great idea, especially if you’re handy with home improvement projects and looking to save money on an already tight budget, but it comes with challenges. The installation process can be overwhelming, requiring proper tools and knowledge to avoid issues while ensuring professional-level results in your house.

Can You Do Spray Foam Insulation Yourself?

If you’ve ever wondered whether you can take on the task of installing spray foam insulation yourself, the answer is a confident yes—with the right preparation. Many homeowners consider the DIY route to avoid the high cost of hiring professional services, but it’s important to know the steps involved and the challenges you might encounter.

DIY Spray Foam Insulation: A Smart Choice?

In today’s DIY culture, many people wonder if they can install spray foam insulation themselves to make their home more energy-efficient. Spray foam is known for its ability to reduce heat loss, significantly lowering the cost of heating and powering your house. Considering the challenges you might encounter, such as ensuring the material reaches all desired areas and handling chemical fumes, it is essential to be well-prepared. You’ll need the necessary safety gear to protect yourself while you work to ensure your DIY improvement project protects you from potential hazards.

The real question many homeowners face is whether the savings justify the effort. Spray foam kits offer a variety of effective options that are not only cost-effective but also relatively simple to use. However, the installation process requires precision. Adding this type of insulation involves preparing the space thoroughly and applying the foam correctly to avoid any gaps that could diminish its effectiveness. If you’re not confident in your ability to handle the installation, hiring a professional might be a better choice to ensure the insulation is added correctly and safely, without the anxiety of potential mistakes. Remember, the goal is to improve your home’s energy efficiency and save money over time without compromising on quality.

What Is a DIY Spray Foam Insulation Kit?

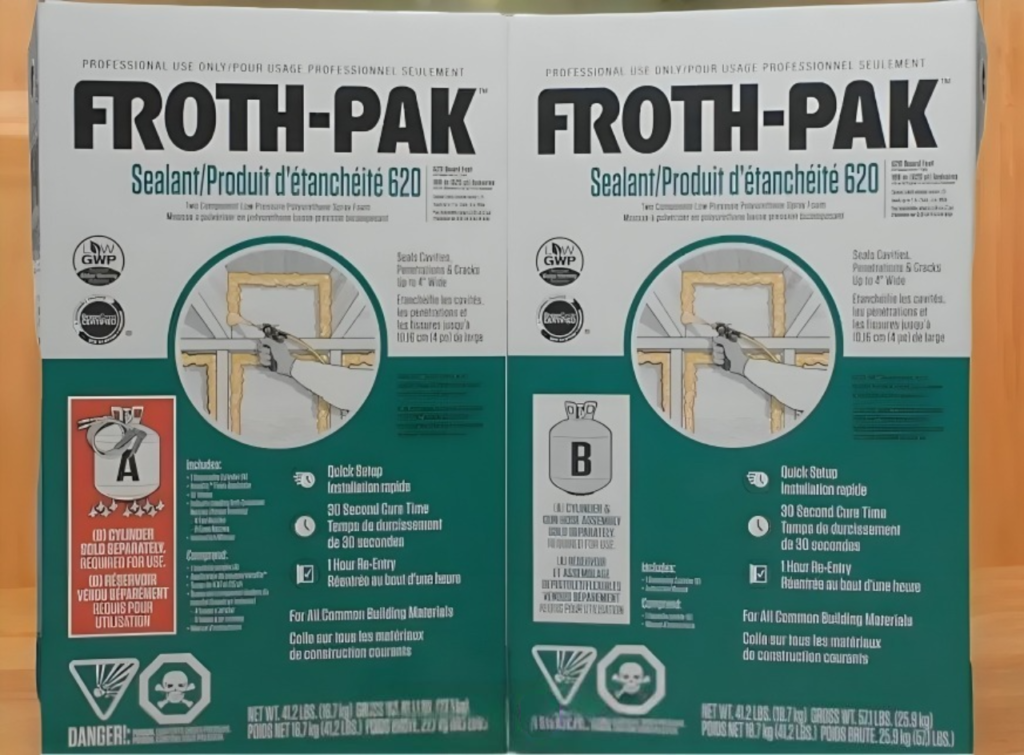

A DIY spray foam kit is an all-in-one solution designed for homeowners who are interested in creating their own spray polyurethane foam insulation. This type of kit comes with everything needed to install the insulation without the need for professional help. Each kit typically includes basic tools such as spray nozzles, a spray hose, and cylinders containing equal amounts of A-Side and B-Side chemicals, which mix to form the foam.

These kits make the job easy and more cost-effective, helping to save a significant amount of money that would otherwise be spent on professional installation services. They are ideal for those with a bit of home improvement knowledge and come with instructions that are easy to understand. The components, like the quick-cure polyurethane foam, ISO (A) cylinder, and Polyol (B) cylinder, along with a dispensing spray gun, are designed to be user-friendly. Even those with just little experience can handle the application, ensuring they can safely install effective insulation in desired areas of their home.

Also Read: DIY vs Professional Spray Foam Insulation: What’s Safer?

How Can You Spray Foam Insulate Yourself?

If you’re considering DIY spray foam insulation, it is essential to plan carefully. Here are five key steps to follow for a successful project.

1: Plan the Scope of Your Insulation Project

2: Get Safety Gear Ready Before You Start

3: Optimize Temperature and Check Equipment

4: Apply Foam Properly to the Ceiling

5: Cover Walls with an Even Foam Layer

Step 1: Plan the Scope of Your Insulation Project

When starting your spray foam insulation project, it’s important to first assess the scope. Identify the areas where insulating is needed, such as walls, ceilings, doors, and windows. This ensures that the project is well-defined and manageable. Smaller projects are often more suitable for DIY, allowing you to achieve precise results without complications.

Step 2: Get Safety Gear Ready Before You Start

Before beginning, make sure to prepare your safety gear. Essential items include a hooded suit, gloves, a face mask, and eye protection. These will protect you from hazards, such as chemical exposure and nozzle clogging, and reduce material wastage. Ensuring your safety gear is in place allows you to work confidently and securely.

Step 3: Optimize Temperature and Check Equipment

For optimal results, maintain proper temperature considerations. The recommended range for application is 75-85 degrees Fahrenheit, with a surface temperature of around 70 degrees. Proper equipment use is crucial; check all tools to ensure they are functioning correctly before application. Following these steps ensures strong adhesion and proper curing of the foam.

Step 4: Apply Foam Properly to the Ceiling

To insulate your ceiling, start by shaking the kit to mix the components thoroughly. Attach the nozzle to the canister, and test it for proper functionality. Apply the spray foam in a side-to-side motion, working evenly in thin layers to reach the desired thickness. Avoid over-spraying to prevent waste and uneven coverage. Let each coat cure before applying the next.

Step 5: Cover Walls with an Even Foam Layer

For walls, hold the applicator gun about 10-12 inches from the surface, and use a sweeping motion for even coverage. Pay attention to corners, edges, and hard-to-reach areas. Work from the bottom to the top, filling the cavities thoroughly. Once the foam has cured and expanded, trim any excess using a utility knife or saw for a neat, finished appearance.

Understanding the Costs of DIY Spray Foam Insulation Kits

When calculating the cost of a DIY spray foam insulation kit, a major factor is whether you choose closed-cell or open-cell foam. Closed-cell foam is rigid, stable, and compact, making it a good option for insulating the insides of walls and other spaces where you want to enhance structural integrity. It is, however, more expensive, and homeowners in cold climates might find it necessary to shell out more for this option due to its higher R-value and better insulation properties.

Conversely, open-cell spray foam is less expensive and known for its relative affordability and ability to expand. This makes it ideal for hard-to-reach places like ceiling cracks and crevices in high places. Open-cell foam is a common option for those looking to patch previously installed insulation or insulate areas around doors and windows. DIY kits for open-cell foam start around $40 and typically contain 12- to 15-board feet of product, sufficient for smaller projects. Closed-cell kits tend to run on average $150 more than their open-cell counterparts. When working on your project, remember to buy any necessary extra hoses and guns, as these items are often needed but not always included in the kits.

Evaluating Cost Savings with DIY Spray Foam Insulation

The potential of DIY spray foam is appealing to budget-conscious homeowners who want to reduce costs without compromising on quality. This premium product often comes with an expensive price tag when installed by professionals, but doing it oneself can result in significant savings. For smaller projects under 100 square feet, a single kit is usually needed, making it a practical and economical choice. These kits are generally less expensive and can reduce the need for professional labor, which is ideal for limited applications.

However, as the scale of the project grows, the complexity increases. Larger areas may require professional-grade equipment and advanced expertise to ensure proper application. While raw materials are priced approximately the same for both online kits and professional supplies, the challenges of handling intricate tasks can negate any initial savings. Additionally, the spray foam insulation cost can vary based on size, tools, and labor, making it more reasonable to hire professionals for bigger jobs. They bring the right knowledge and tools, ensuring efficient results without unnecessary stress.

Risks of DIY Spray Foam Insulation

Potential Health and Financial Risks

While DIY spray foam insulation can seem like a cost-saving option, it does not entirely live up to its appeal. The method of installing spray foam yourself poses both financial and health risks. It’s important to examine these risks before starting your project. A chemical reaction occurs when spray foam is applied, and during this process, off-gassing is produced. This normal byproduct releases toxic fumes into the air, and breathing these fumes can be dangerous, potentially leading to respiratory problems.

To ensure safety while spray foam insulating, it’s crucial to properly prepare. Before starting, you must make sure you have the right safety gear. This includes a hooded suit, gloves, a face mask, and eye protection. Without these precautions, the risk of exposure to toxic fumes becomes much higher, putting your health at risk. Always weigh the potential dangers against the savings you might get from taking on a DIY spray foam project.

When installing spray foam insulation, it’s crucial to be aware of the risks and take necessary precautions. Professional contractors typically wear ventilators to ensure they can breathe fresh air during the process, and homeowners pursuing the DIY route must also secure appropriate personal protective equipment (PPE). It’s important to contact the manufacturer of the DIY spray foam kit to get specific, accurate information on the equipment needed. Off-gassing fumes are a normal part of the process, and proper ventilation is essential to direct the fumes outside the home. Using a fan to create air exchange helps in sending the fumes out of the space, reducing potential risks for the homeowner.

Potential Risks of Off-Ratio Foam in DIY Spray Foam Kits

When using DIY spray foam kits, there is a greater likelihood that the foam will be off-ratio due to the minimal controls available. Off-ratio foam is the result of a chemical reaction where one chemical component is either too much or too little, leaving an unstable product. Unlike on-ratio foam, which is safe and inert, off-ratio foam can never cure properly. This means it should never be left in someone’s home as a finished product because it may continuously release toxic fumes into the air. Without the right balance of each chemical component, the foam remains incomplete and can pose serious risks to health and safety.

In professional installations, contractors use specialized equipment to monitor temperature, pressure, and the precise ratio of chemicals. However, DIY kits do not offer this level of control, making it almost impossible for an untrained eye to determine if the foam has gone off-ratio. Visual differences such as color may be mistaken for normal foam variations when in fact, the foam has failed to cure properly. This can lead to long-term issues, as the excess chemicals can continue to off-gas indefinitely, creating hazardous conditions in the home.

The Mess of Cleaning Up Failed DIY Spray Foam

When failed spray foam occurs, it can create a real mess. The consistency of failed foam is similar to glue, making it tacky to the touch and very difficult to remove. In most cases, special chemicals are required to loosen the foam’s adhesion to the substrate. For small projects, this issue might be irritating, but it’s usually manageable. Removing up to 100 square feet of foam can be a frustrating, yet doable project that might take a weekend to complete.

However, when dealing with larger projects, the cleanup becomes much more challenging. Cleaning up extensive amounts of sticky foam can quickly become overwhelming, especially if the foam has covered a large area. Tackling these larger projects requires patience and more effort, as the sticky foam spreads and hardens, making it tough to handle.

Also Read: How to Remove Spray Foam Insulation Without the Hassle

The Financial Risks of DIY Spray Foam

When you undergo a home improvement project like DIY spray foam, there’s no safety net in case of product failure. The lack of insurance is a massive concern, especially if the product is likely to fail. With so little control over reaction variables, the possibility of DIY spray foam failure is high. This could lead to a significant financial risk, particularly with large projects where you might end up spending almost as much as hiring a professional.

Imagine investing time and money into a DIY project, only to realize that the foam didn’t apply correctly. You may then need to hire a professional anyway, effectively doubling your costs. DIY spray foam can cost twice as much if you have to start over because the initial application failed. While DIY may seem like a good way to save money, the risks of product failure make it a gamble for larger, more complex projects.

Best Places to Use a DIY Spray Foam Insulation Kit

A DIY Spray Foam Insulation Kit is the perfect choice for sealing various areas in your home, offering maximum benefits when used in the right spots. It can be applied in the attic to seal gaps and holes, helping to prevent air leakage and reduce energy bills. It is also highly effective for filling open wall cavities, improving thermal insulation in the process. For crawl spaces and the rim joist, where common air leaks tend to occur, using spray foam can improve insulation and boost your home’s energy efficiency.

Around windows and doors, it’s important to use spray foam insulation to seal gaps and cracks, effectively preventing air leakage and maintaining comfort indoors. It’s also useful for patching existing insulation to improve effectiveness. When working with a DIY spray foam insulation kit, make sure to carefully follow all instructions and take the necessary safety precautions. If you are unsure about the application process, consulting a professional insulation contractor can be very helpful.

Final Thoughts on Installing Spray Foam Insulation Yourself

DIY spray foam insulation is best used for small projects where the greatest cost savings and the least risk are involved. These DIY kits contain the same chemical components as professional-grade kits, but the equipment is of much lower quality. For homeowners with basic expertise and the ability to follow strict directions, installing spray foam insulation could be manageable. However, if you’d rather avoid the hassle of the work, it’s better to call a professional, who will likely charge between $1,350 and $4,500 on average for a complete job.

For small projects that only need a single DIY kit, doing it yourself can save money on labor costs. However, for larger jobs or when multiple kits are required, hiring a professional can ensure a safer, higher-quality finish that’s backed by insurance.

Not sure whether to DIY or hire a contractor? Contact us today, and we’ll connect you with trusted spray foam insulation professionals who can handle the job efficiently and safely, giving you peace of mind and long-term savings. Avoid costly mistakes — let the experts help!

FAQ

Is DIY spray foam insulation worth it?

The short answer is NO. While smaller projects like insulating corners of doors and windows with DIY foam may be doable for experienced crafters, applying spray foam insulation is a task better left to trained professionals to ensure proper application and effectiveness.

Is spray foam insulation easy to install?

Fiberglass insulation is often perceived as the easiest insulation for homeowners to install, but it does not create an airtight seal, allowing heat to escape. Fortunately, both closed-cell and open-cell spray foam insulation are just as easy to apply, offering better sealing and energy efficiency

Can I do spray foam insulation by myself?

The answer is yes, but you must remove drywall before you install spray foam insulation. When spray foam expands rapidly inside walls, failing to remove the drywall can cause it to overfill the panel and exert pressure on the plasterboard, potentially leading to damage.

How to apply spray foam insulation in a can?