When it comes to spray foam for insulation, making the right choice can be trickier than it seems. Both closed cell and open cell foams insulate your home in different ways. If you ask anyone about the job, you’re bound to get a few different answers. Some people are always saying one is better than the other, but the truth is, it necessarily comes down to the specific application. What are your goals? Are you trying to reach a high R-value, or do you need to maintain a tight budget?

In this guide, we’ll examine the differences and similarities between open cell vs closed cell spray foam. Pick the one that fits your project needs, whether it’s for jobs requiring flexibility or rigidity. It’s not a matter of one being better than the other, but of finding the best product for the job.

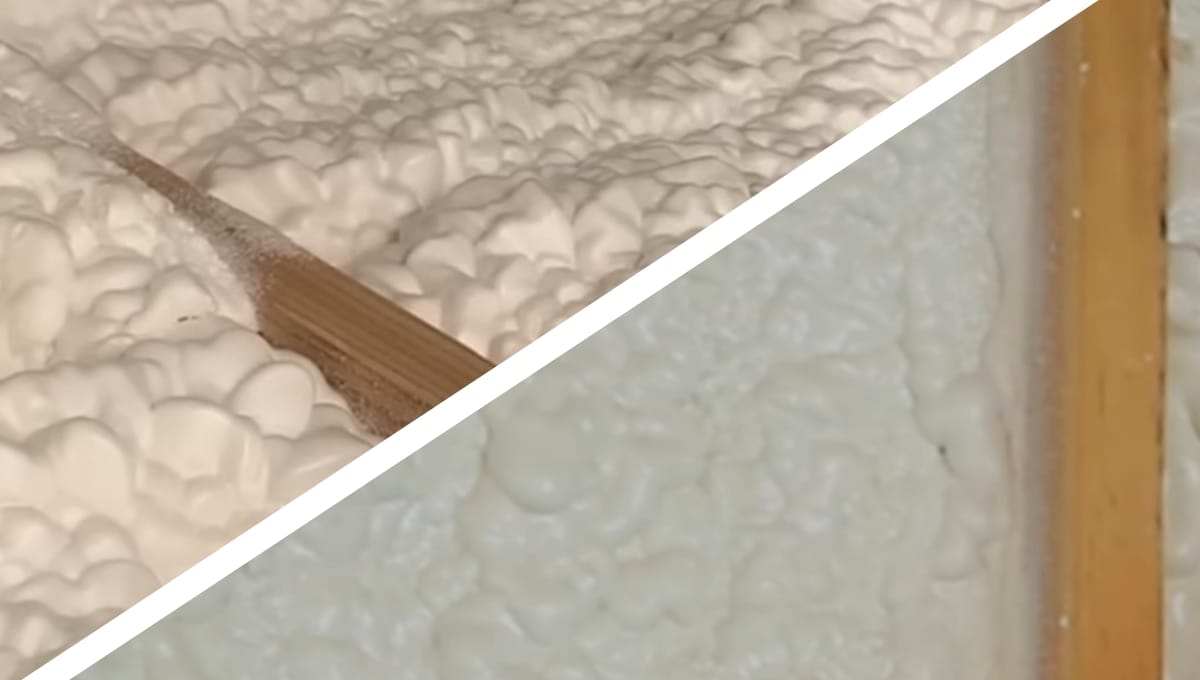

Which Spray Foam Insulation Is Best?

The best spray foam insulation depends on your needs. Open cell is great for soundproofing and is more budget-friendly, while closed cell offers better insulation with a higher R-value. If you need strong moisture resistance and energy efficiency, closed cell spray foam is the best choice. However, for flexibility and affordability, open cell spray foam works well. Understanding their differences and similarities will help you choose the right one for your specific application.

What is Closed Cell Foam?

Closed cell foam is made up of tiny air pockets that are piled in a compact configuration, almost like inflated balloons nestled tightly together. The closely packed cells make it vapor semi-impermeable and much more rigid compared to other types of foam. This structure allows it to withstand greater pressure and makes it about 4 times denser than open cell foam. Because of these qualities, closed cell foam is often chosen for projects where strength and resistance to moisture are critical.

What is Open Cell Foam?

Open cell foam is made through a similar process as closed cell foam, but its cells are broken instead of closed, making it vapor semi-permeable. This formation allows air to pass through the material more easily, much like the holes in a sponge. Because of this, open cell foam is more porous and absorbent, making it suitable for situations where flexibility and breathability are important.

What’s the Difference Between Open Cell and Closed Cell Foam Insulation?

Open cell and closed cell foam are two different types of spray insulation, each with its own strengths and weaknesses. Neither is necessarily better than the other; it really comes down to understanding the benefits and choosing the type that fits your needs. Open cell foam is lighter and more absorbent, making it great for filling gaps, cracks, and cavities, while closed-cell is denser and more rigid, often used for preventing airflow and adding structural support. Both are formed from chemicals like isocyanate and polyol resin, which are mixed in a chemical reaction that emerges as a liquid and then expands into a semi-solid foam.

Understanding the Cell Structure of Foam Insulation

Open cell foam, often called softer, has room inside each cell like a little air bubble, making it more flexible. It can allow water to pass through, but some brands like Icynene are hydrophobic, meaning they can retain less than 5% water on contact and keep their shape as the cell structure dries naturally. Other brands can retain up to 75% of their weight in water. In contrast, closed cell foam is the exact opposite, with no space between densely packed cells, making it much more rigid and preventing air and moisture from passing through. This rigidity also adds to the structural integrity of a building once it’s installed. Open cell and closed cell each play a vital role in creating an air barrier and sealing the building envelope of a home.

Understanding Foam Density

The density of spray foam plays a big role in its performance, with a direct correlation to its cell structure. Open cell foam is much softer and more flexible, with a core density of typically 0.5 pounds per cubic foot. This lighter density makes it great for sound dampening as the thicker, softer material helps to reduce sound waves more efficiently. Conversely, closed cell foam is denser and heavier, with a density ranging from 1.75 to 2.2 pounds per cubic foot. It’s about three to four times heavier than open cell foam, which gives it a tighter, more rigid structure that can perform better in certain applications.

R-Value and Expansion: Open Cell vs Closed Cell Foam

When comparing open cell foam and closed cell foam, one of the main differences is the density and how much each can expand. Open cell foam has a lighter density and a bigger cell structure, allowing it to expand more—typically 100 to 120 times its size. In contrast, closed cell foam only expands about 33 times its size, making it denser. The culmination of expansion and density in each type of spray foam directly impacts their R-Value, which measures their ability to insulate. Open cell foam usually has an R-Value of 3.5 to 4 per inch sprayed, while closed cell foam offers a much higher R-Value—typically 6.0 to 7 per inch.

However, a higher R-Value does not always mean better performance. The biggest reason for heating and cooling loss in a home is often due to air leakage. With products like Icynene, you can create an air barrier at a thickness of just 1.25 inches with closed cell foam, or 3 to 3.5 inches with open cell foam. In a typical wall cavity, closed cell foam installed at 2 inches provides around R14, while open cell foam at 3.5 inches gives approximately R13. Despite their differences, both foams effectively block conditioned air from leaving and prevent unconditioned air from coming in, making their thermal performance nearly identical in most cases.

Cost of Open Cell vs Closed Cell Foam

When comparing closed cell foam and open cell foam, one of the biggest factors is the cost of spray foam insulation. Closed cell foam is denser and uses more material to cover the same amount of space, which makes it cost more. It also requires more labor when being installed due to its heavier structure. On the other hand, open cell foam is more economical and less expensive to use, as it needs less plastic and still achieves good thermal insulation. The chemical makeup and expansion rates also play a role, with open cell foam expanding more and requiring less material. Selecting the right material depends on many factors, like the properties of each foam and the decision of engineers and manufacturers, who often weigh these considerations carefully.

Air Permeability in Foam Insulation

Closed cell foam acts as a better air barrier because it is less permeable and can control airflow more effectively than open cell foam. For example, it could be used as a highly effective gasket or seal in climate-control situations, helping to prevent hot outside air from entering an air-conditioned enclosure. On the other hand, open cell foam is more effective for filtration as it allows air to pass through. For instance, it can be a suitable air filter for an engine, as it can capture dust and pollutants without restricting air flow.

Waterproofing with Spray Foam

Closed cell foam is more useful than open cell foam when it comes to preventing water vapor from passing through. It is almost completely impermeable to water, vapor, and air, making it less likely to be structurally impacted by the common issues like water damage, mold, mildew, rot, or even bacteria. This makes closed cell foam an excellent choice in areas where moisture protection is crucial.

Water Absorption in Spray Foam

Open cell foam has a higher possibility of absorbing water compared to closed cell foam, which can lead to degraded performance, especially in thermal applications. While engineers do not necessarily strive for perfect vapor impermeability, the free flow of water can be detrimental to the structure as it can trap water. If the environment is moist, closed cell foam might be the better option to work with, as it is less likely to absorb water and become an ineffective insulator. For example, closed cell foam is better suited for wrapping a water tank.

Heat Insulation Performance

Both open and closed cell foam are efficient thermal insulators, but their performance can vary depending on the application and environmental factors. In a moist environment, one type of foam might perform better than the other. For example, open cell foam may not perform optimally in thermal applications when used in moist or humid environments. Much like a wet sponge, it will not retain or deflect heat effectively because water is a poor insulator compared to air.

Soundproofing with Spray Foam

Open cell foam typically performs better than closed cell foam when it comes to absorbing and reducing sound. This is due to its permeability and the open cell structure, which allows sound waves to interact with residual membranes. As a result, the energy from the sound is transformed into heat, effectively absorbing some of the sound.

Benefits of Open Cell and Closed Cell Foam

Before we look at the benefits of each type of spray foam, let’s take a second to recap the science behind them. Open cell spray foam is lighter and less dense, expanding 100-120 times its size. Because of this, it has a lower R-Value, typically around R3.5-4 per inch when installed. Closed cell spray foam, on the other hand, is heavier and denser, expanding only up to 33 times its size, which leads to it having a higher R-Value, usually around R7 per inch when sprayed.

Advantages of Closed Cell Foam

Closed cell foam is often the best choice when space is an issue and you need robust insulating performance. It can achieve up to 2x the R-Value of open cell foam inside a standard wall, making it ideal for tight spaces. Its rigid nature also adds structural integrity to the building. With E84 fire-rated versions available, closed cell foam acts as a vapor barrier, keeping water and moisture out of the home, and is unharmed by water damage. In areas prone to flooding, it is FEMA recognized as flood-resistant, able to reject bulk water without deteriorating. This foam also works well as a vapor retarder and can be sprayed on the exterior of buildings, making it the best solution for tough applications. Its rigidness helps reinforce structures like a pole barn in high winds, preventing metal flex and offering extra strength.

Advantages of Open Cell Foam

Open cell spray foam has many benefits when using it for a home or project. One of the biggest advantages is the overall cost, which is considerably less than closed cell spray foam due to the material costing less to manufacture. Since it expands much more, it can insulate the same amount of space while using less material, potentially saving on labor costs. It fills every nook and cranny much easier, ensuring a proper air barrier even in difficult-to-reach spaces, which ultimately helps to keep conditioned air inside.

Additionally, some products like Icynene’s Classic Ultra Open Cell Spray Foam are hydrophobic, meaning they retain less than 5% of their weight in water if exposed to a leak, and won’t need to be replaced if allowed to dry. This makes it superior to traditional insulation like fiberglass, which can soak up water and lead to mold. Another benefit is that pests and rodents do not like it, as it offers no food value, reducing the chance of finding critter homes in your attic or crawlspace. Moreover, it effectively dampens soundwaves, making your home not only insulated but also quiet. However, it is not ideal for locations with extreme weather temperatures.

Selecting the Right Foam for Your Application

When choosing between open cell foam and closed cell foam for your application, it often comes down to the specific needs of the project. If your building code demands a higher R-Value per inch, then closed cell foam may be the best option to meet those code requirements. It provides a better seal, especially for exterior projects where the foam could be exposed to continuous water, as it is FEMA approved and designed to reject bulk water. On the other hand, open cell foam offers significant cost savings, with reduced material and labor costs. This foam works well for tough areas that are difficult to access like nooks and crannies, thanks to its high expansion rate. Ultimately, the choice depends on what the consumer is looking for, as both types of spray foam will help seal up a home and drastically reduce heating and cooling costs over the life of the structure.

Final Thoughts

Investing in proper insulation depends on your home improvement needs and budget. While open cell is more affordable, closed cell is a better option for areas requiring a higher R-Value. It offers more versatility, making it ideal for various applications. If your building code demands better insulation, investing in closed cell foam ensures you meet requirements. Though it may be more expensive, the features and durability make it a smart investment in the long run. Whether you need cost-effective insulation or a high-performance project, understanding the differences helps you make an informed choice.

FAQ

Which Is Better, Open or Closed Cell Foam Insulation?

Closed cell foam is better for insulation because it has a higher R-value, around 6.0 per inch, while premium types like Tiger Foam’s E84 Closed Cell formula can reach 7 per inch. It provides a higher rating for keeping heat in or out of a structure. Meanwhile, open cell foam is softer and better for soundproofing but less effective at insulation.

What Are the Disadvantages of Open Cell Foam Insulation?

While open-cell foam is less expensive and excellent for soundproofing, it has some disadvantages. It has a lower R-value per inch, making it unsuitable for moisture-prone areas. Since it can absorb water, it may not be the best choice for high-humidity spaces compared to closed-cell foam.

Can Mold Grow in Open Cell Foam Insulation?

Spray foam insulation lacks organic material, so mold spores have nothing to feed on. This makes it highly effective in preventing mold growth compared to other materials.

What Is the R-Value of 5.5 Inches of Open Cell Foam?

5.5 inches of spray foam has an R-value of 6 per inch, meaning it can achieve an R-value of 30. This measures how well the material resists heat transfer. A higher R-value means a better insulator, keeping homes more energy-efficient.